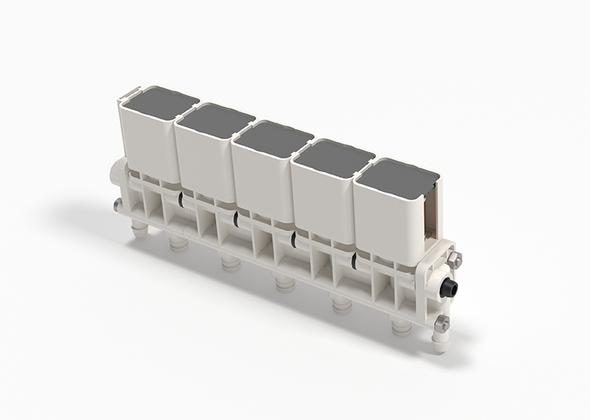

Modular valve block with quick-acting valves

For pressure and vacuum applications as well as fluid control

The modular valve block for pressure and liquid applications is versatile and ideal for complex applications. It enables the precise control of air, neutral gases, liquids and steam in pneumatic applications with periodic air supply.

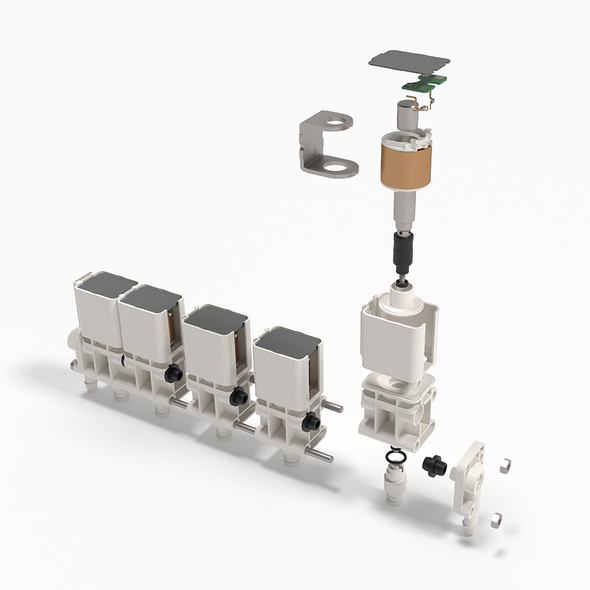

With a flexible number of electromagnetic switching valves that can be combined as required, the valve block offers individual configuration. The block assembly with bayable individual valves and modular flange offers customization options for specific requirements.

Quick connectors for pneumatic hoses enable efficient installation and rapid replacement of components. The valve components have proven their robustness and reliability in extensive tests and are already being used successfully in various applications and industries.

The valve block is ideal for control and dosing applications that require maximum precision and reliability. Medical applications include the control of decubitus mattresses for pressure relief and instrument supply in dental units. Industrial applications include air distribution in manufacturing plants, switching technical gases and use in the food and packaging industries.

Key features

- Meets the highest leakage requirements

- Fast response time

- Long service life (5k to 1.5 million cycles, maintenance-free) over a wide temperature range

- Modular design for combining different nominal sizes and types

- Versatile configuration thanks to a flexible design principle

- Cost-efficient solution thanks to high quantities and standardized components

Application examples

- Decubitus mattresses for pressure relief (care mattresses, soft positioning mattresses)

- Dental unit | Dental cleaning devices | Instrument supply in dental treatment units

- Water management, care product control, supply and drainage of water or disinfectant

- Air cushion control for optimum patient comfort

Other sectors & possible applications

- Air distribution in industrial production facilities

- Switching of technical gases

- Water or cleaning agent distribution for sensor cleaning

- Compressor or vacuum systems

- Food and packaging industry